SCROLL DOWN

SCROLL DOWN

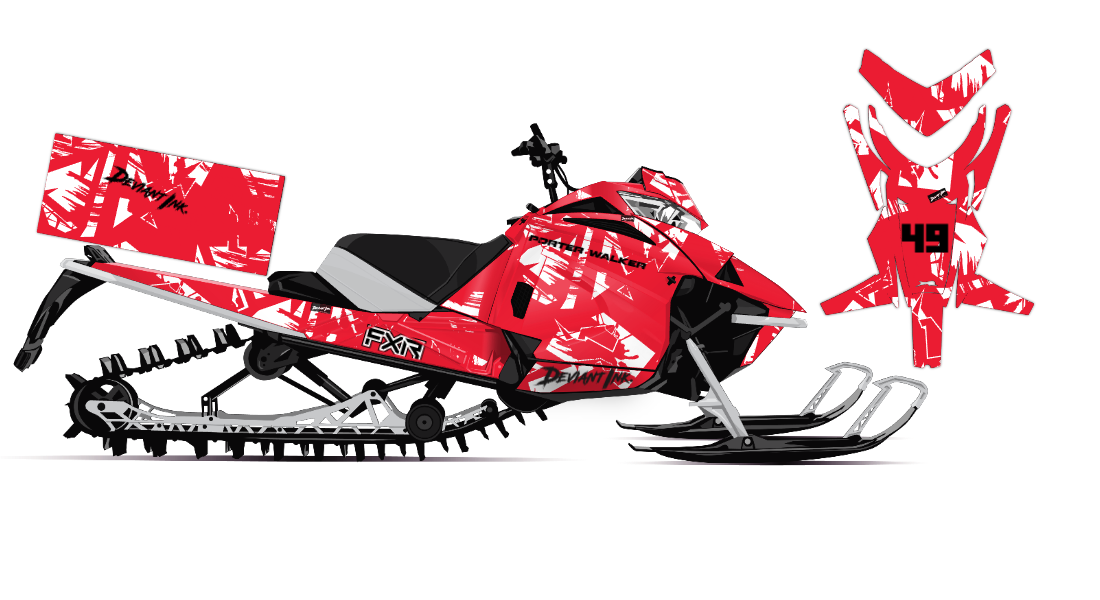

![]() porter

w.

porter

w.

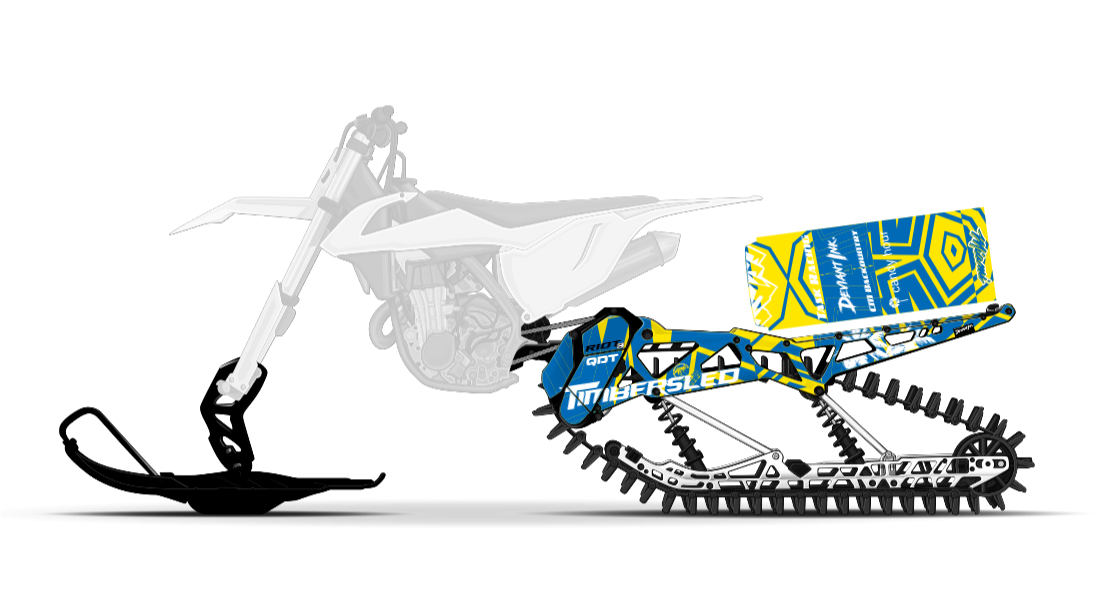

![]() Landon

C.

Landon

C.

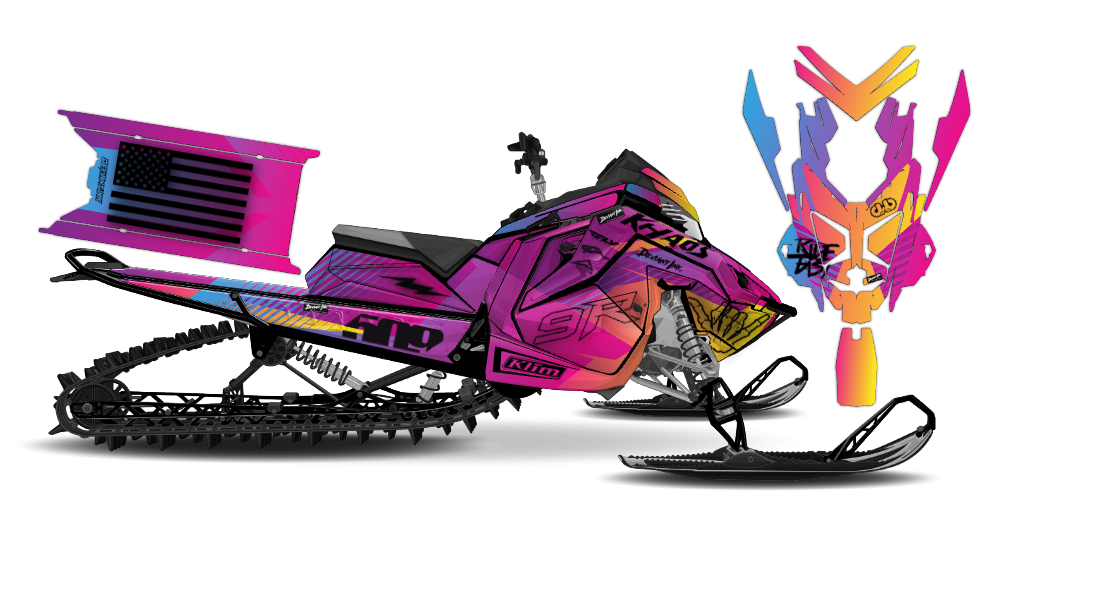

![]() Johannes

K.

Johannes

K.

![]() Émile

l.

Émile

l.

![]() Jordan

J.

Jordan

J.

![]() Ron

P.

Ron

P.

![]() Makenzie

M.

Makenzie

M.

![]() McCoy

M.

McCoy

M.

![]() Kaden

j.

Kaden

j.

![]() Caleb

H.

Caleb

H.

![]() Landon

W.

Landon

W.

![]() Madison

A.

Madison

A.

![]() Michael

K.

Michael

K.

![]() Justin

B.

Justin

B.

A guide to help you design a polished wrap of your own. We will walk you through the process from start to finish including color selection, logo placement, coverage, and overlay.

START HERE

SHINY • REFLECTIVE

SHINY • REFLECTIVE

GLOSSY • GOLD METALLIC FLAKES

GLOSSY • GLITTERY METALLIC FLAKES

This piece is a great place for logos and is dependent on track/tunnel length.

This area differs depending on make/model/ year. Make sure to select correctly in order to get the best fitting piece for your vehicle.

This is another great area for logo placement and giving a strong finished look to your vehicle.

This is the most essential area of a sled. With the most coverage of any section, you will best see your sled transformation.

Our top layer laminate is guaranteed to protect against the toughest of conditions no matter where you ride.

CMYK isn’t enough so we added more colors to our printers.

Built with micro air channels making installation bubble free so you don’t have to worry about messing up.

Layered with extra adhesion in order to bond to any plastic, metal, or glass imaginable.

*This timeline is a general timeline to help illustrate what the order fulfillment process is and around how long it will be from the time the order is placed until you receive it. The timeline is heavily dependent on several factors out of our control:

Customer places custom wrap order. This is where the fulfilment process begins.

If everything looks good, customer approves the proof for printing.

The designer will prepare the approved mockup for print and send it off to the production team.

Here, the production team runs the wrap through two machines to get it laminated and cut.

It is now given to a shipping service to deliver to your doorstep.

Design team creates a digital version of custom wrap as designed by the customer online. He/she then sends it to customer for approval prior to printing.

If there is anything unsatisfactory with the mockup (ex: misspelling, color changes, logo additions, etc.) the customer will request the change and wait for the designer to create an updated mockup

This is where the digital design starts to come to life. Once printed, the ink takes up to a day to dry

Now that the wrap is printed, laminated and cut it’s ready to be boxed and shipped.

Customer places custom wrap order. This is where the fulfilment process begins.

Design team creates a digital version of custom wrap as designed by the customer online. He/she then sends it to customer for approval prior to printing.

If everything looks good, customer approves the proof for printing.

If there is anything unsatisfactory with the mockup (ex: misspelling, color changes, logo additions, etc.) the customer will request the change and wait for the designer to create an updated mockup

The designer will prepare the approved mockup for print and send it off to the production team.

This is where the digital design starts to come to life. Once printed, the ink takes up to a day to dry

Here, the production team runs the wrap through two machines to get it laminated and cut.

Now that the wrap is printed, laminated and cut it’s ready to be boxed and shipped.

It is now given to a shipping service to deliver to your doorstep.

* This time is calculated from the time the final proof is approved by the customer. This time also will fluctuate based on the time of year and how many orders we have in the queue as well as other uncontrollable variables.

Tracking info will be emailed once your package is in transit. International import taxes and duties are receiver's sole responsibility. All domestic US orders ship via FedEx or UPS fully insured. All international orders ship via FedEx uninsured (by popular demand)in order to save on import taxes and duty fees.

Orders print and ship out within a week—schedule allowing. Custom and large quantity orders may require additional time. We take each order one at a time and we operate using an on-demand model. What does that mean? It means that we print everything as it’s ordered—we’re not stockpiling kits printed overseas.